Call us: 08045811672

Showroom

Lamination Plant deepens and intensifies the colors. It improves contrast. Lamination provides your items a polished, professional appearance. We not only provide longer durability, but we also believe in cost-effective production, which gives your manufacturing unit a huge boost.

Textile Roller is coated with materials that have been proven to be acceptable for all finishing techniques. This is ideal for classic, contemporary, and technologically innovative textiles. There are several textiles available, and each has unique features in terms of substance, structure, and flexibility.

Lamination Roller melts glue is injected into the lamination film using heated rollers. This film is placed on a substrate such as paper or card using pressure rollers. It is usually utilized by printers or print finishers for high-volume/quality output. This is safe to use.

Cylindrical Roller has a high load capacity when subjected to mostly radial stresses. Because of the low friction between the rollers and the ring ribs, these bearings are suitable for high-speed rotation. These rollers of cylindrical roller bearings are in linear contact with the raceways.

Industrial Rubber Roller is essentially rubber-covered metal pipes used in a variety of industrial applications such as conveying, printing, laminating, and sealing. The roller is agricultural equipment that is used to flatten ground or break up huge clumps of soil, particularly after plowing or disc harrowing.

Conveyor Plant is designed and manufactured by making use of premium-grade raw materials and upgraded technology. It reduces labor expenses while increasing productivity. When delivering things from one area to another, conveyor systems save time. Material movement on several floors is simplified.

Conveyor Roller is a type of conveyor belt that uses rollers, which are equally spaced revolving cylinders, to allow things to skate on its surface. This transports stuff from one location to another, frequently utilizing gravity or tiny engines.

Steel Roller is most typically employed in conveyor systems in a variety of sectors, including mining and construction. This roller is required even in large-scale shipping, packing, and distribution warehouses, manufacturing plants, recycling facilities, and tiny fabrication shops.

Hard Chrome Plating Roller has a Rockwell scale of 68-70, making it appropriate for a wide range of industrial applications requiring corrosion and wear resistance. It is also the best-plated metal deposition to use when specifications ask for smooth and perfect roll-face features.

Engraving Roller is tested under various parameters to ensure its high quality and effectiveness. A continuous printing method in which the print pattern is etched on a hefty copper cylinder and then electroplated with chrome for longevity. This is very effective to use.

Chilling Roller is highly efficient, and the size and patterns may be modified. This is typically utilized in food, optical film, solar cell, different sheets, LCD screens, optical film coating equipment, and pharmaceutical packaging sectors. This requires very low maintenance and replacement costs.

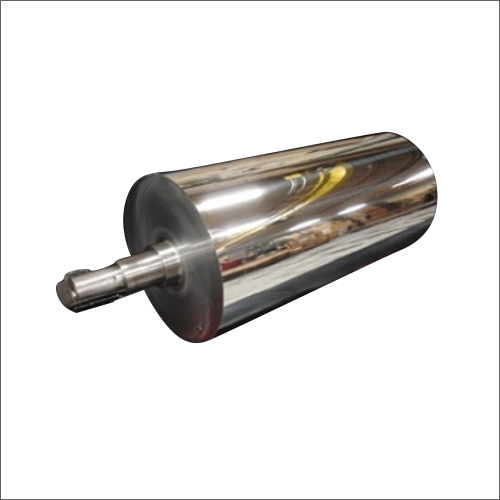

SS Roller containing at least 10.5% chromium. Other alloys are added to improve the structure, corrosion resistance, machinability, formability, and strength. This comes with varying amounts of nickel, molybdenum, titanium, and copper. The qualities of stainless steel are derived from the combination of these alloys.

MS Roller meets international standards and has qualities like as high-temperature resistance, tear resistance, wear resistance, corrosion resistance, and much more. This roller is used in various industries like the flexible/plastic industry, textile industry, paper industry, leather industry, sheet line industry, and other industries.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese